Reverse Logistics

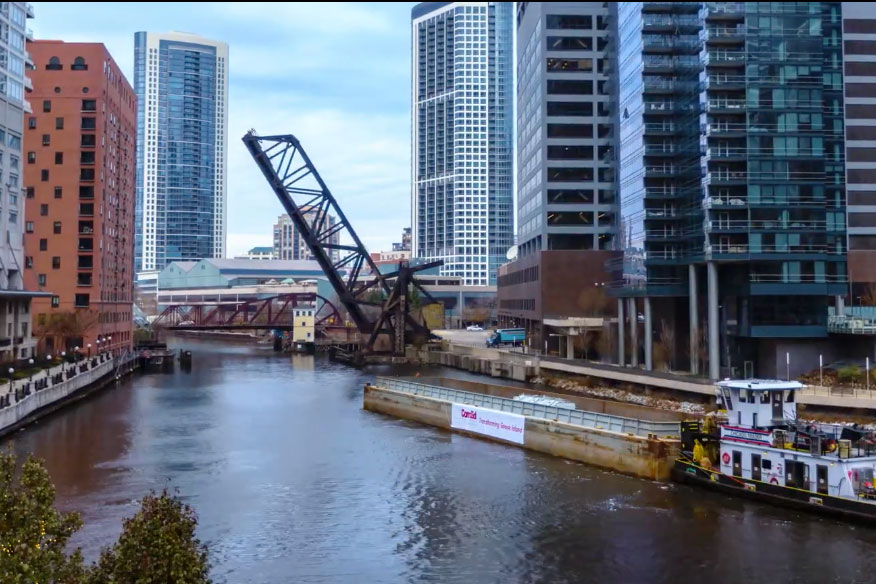

Our customer required a refurbishment and fulfillment facility centrally located to ensure serviceable inventory country-wide. The primary objective is to receive, assess and process their inventory coming back from construction sites to bring back into service for re-use. Logisticus built an operational plan to operate the facility full time and is providing warehouse services, long-term storage, crane and offload services, inventory management, TMS, procurement and reporting. The location is highly unique given that it has truck, rail and barge access all on one site. The facility has 6 product lines, custom TMS to support inventory management of primary and secondary skus (~150). The solution was in place within 2 weeks from notice to proceed. As a result of our performance, this warehouse has become the centralized warehouse for all activity for our customer.